Overview

Augmented reality (AR) is revolutionizing automobile manufacturing by significantly enhancing production efficiency, accuracy, and safety. Real-time digital overlays guide workers and streamline processes, illustrating the profound impact of AR in this sector.

Applications such as:

- Assembly support

- Training

- Quality control

exemplify how AR integration leads to substantial market growth and notable cost savings in the automotive industry.

Research indicates that embracing AR not only optimizes operations but also positions companies at the forefront of innovation. As the industry evolves, it is imperative for brand managers to consider collaboration with AR developers to harness these advancements and drive their organizations forward.

Introduction

The integration of augmented reality (AR) in automobile manufacturing is fundamentally reshaping the industry, merging digital innovation with traditional production methods. This technology streamlines assembly processes and enhances training and quality control, offering manufacturers a significant competitive edge. As the automotive sector rapidly evolves, companies must effectively leverage AR to tackle challenges such as human error and operational inefficiencies. Exploring these critical questions reveals the transformative potential of augmented reality in driving the future of automobile production.

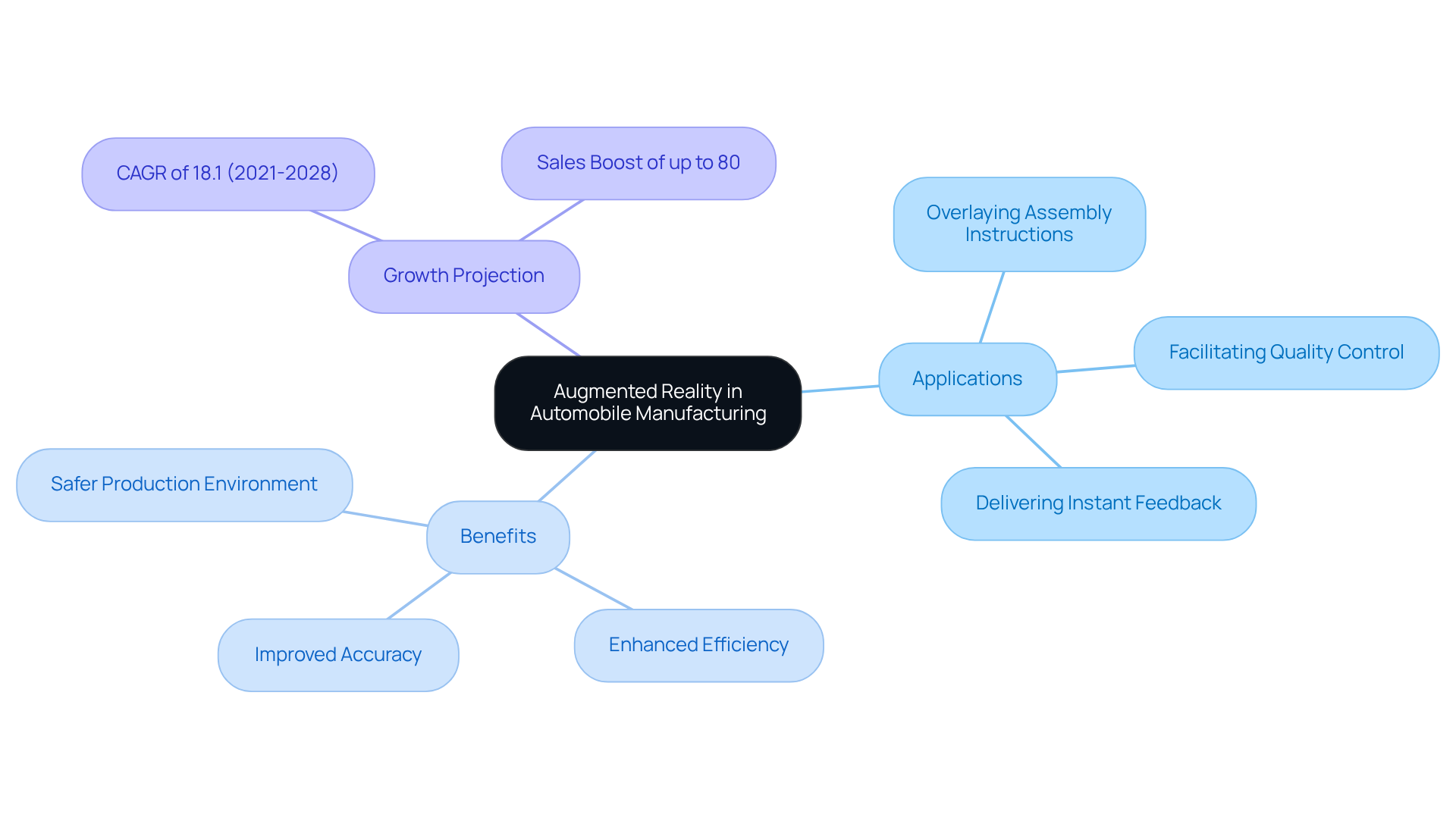

Defining Augmented Reality in Automobile Manufacturing

Augmented reality in automobile production represents a transformative integration of digital information with the physical environment, significantly enhancing production activities. This technology overlays computer-generated images, sounds, and other sensory enhancements onto real-world views, enabling manufacturers to visualize complex data in real-time. For example, AR equips assembly line workers with visual instructions directly on the components they are handling, thereby improving accuracy and efficiency. This innovative approach not only simplifies assembly processes but also enhances training and maintenance activities, positioning augmented reality in automobile as an essential resource in the construction of modern vehicles.

Notably, augmented reality in automobile applications encompasses:

- Overlaying assembly instructions

- Facilitating quality control

- Delivering instant feedback to workers

These functionalities not only bolster production efficiency but also foster a safer and more sustainable production environment. The incorporation of augmented reality in automobile is projected to expand at a CAGR of 18.1% from 2021 to 2028, highlighting its growing importance in the automotive industry.

Leading manufacturers are already harnessing augmented reality in automobile technologies to enhance and optimize their operations. For instance, Ford's Advanced Manufacturing Center focuses on AR, robotics, and 3D printing to streamline production, while Toyota has partnered with Microsoft to enhance training efficiency. Such initiatives illustrate the profound influence of augmented reality in automobile on the future of vehicle production. As the industry evolves, collaboration and investment in AR technology will be crucial for staying ahead in this competitive landscape.

The Evolution of Augmented Reality in the Automotive Industry

The evolution of augmented reality in automobile began in the late 1980s with General Motors' introduction of heads-up displays (HUDs), which projected essential information such as speed and turn signals. However, it was in the early 2000s that augmented reality in automobile technology truly gained traction, as companies like BMW and Ford began to explore its design and marketing potential.

By 2015, augmented reality in automobile manufacturing had firmly established its presence, with major automakers integrating AR solutions into assembly lines and maintenance protocols. This shift marked a significant milestone, as AR became a vital component of Industry 4.0, facilitating operational optimization, error reduction, and enhanced training through immersive experiences.

Notably, Magic Playbox has been at the forefront of this transformation, pioneering immersive AR experiences that bolster brand engagement and foster customer loyalty. The global vehicle AR market is projected to grow from USD 3.97 billion in 2020 to USD 14.44 billion by 2028, underscoring the increasing adoption of AR technologies by manufacturers.

Today, AR not only streamlines manufacturing processes but also enriches the user experience, showcasing the transformative potential of this technology within the automotive sector.

Key Applications of Augmented Reality in Automobile Manufacturing

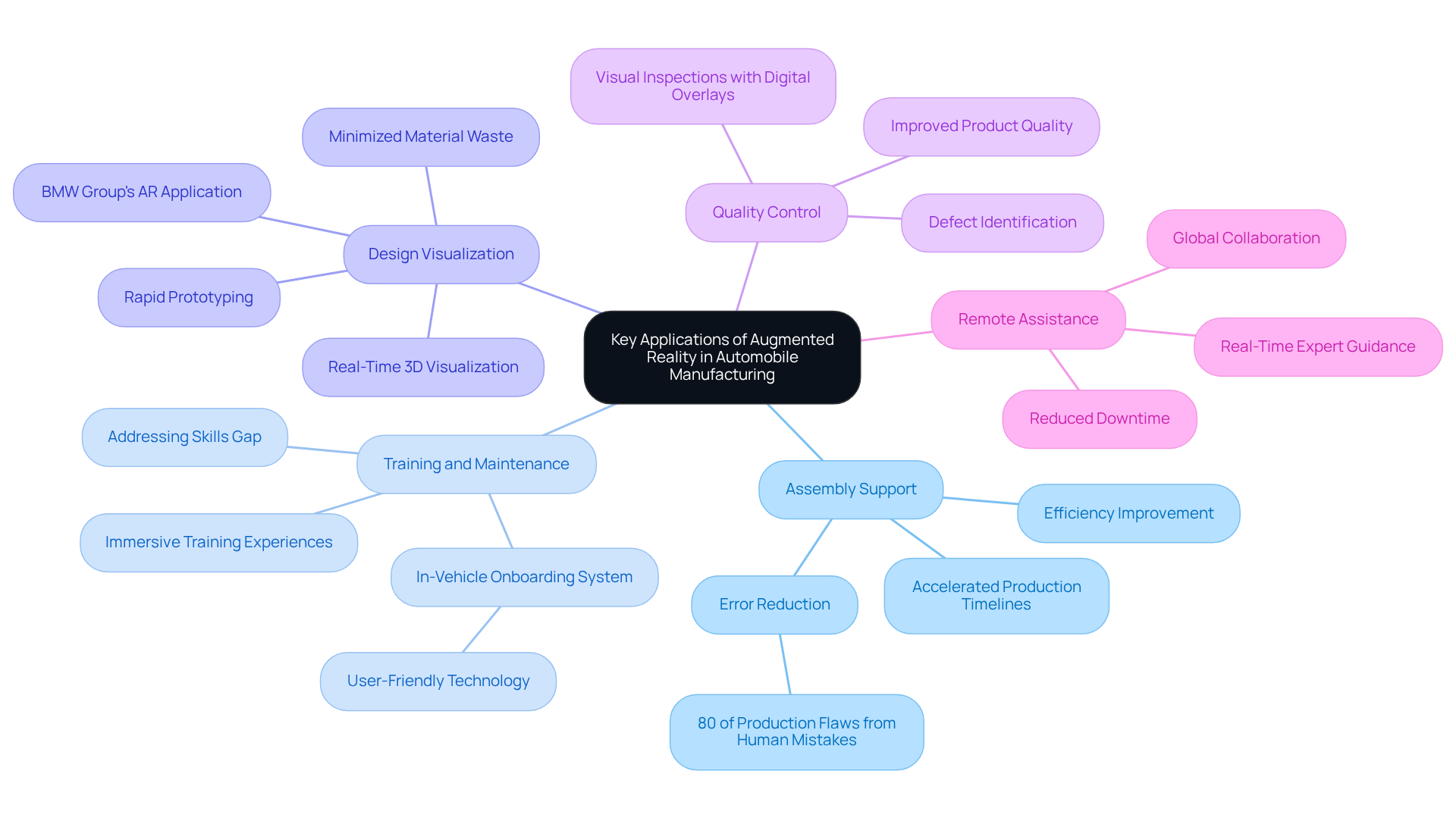

Key applications of augmented reality in automobile manufacturing are transforming the industry significantly:

- Assembly Support: AR systems enhance manufacturing efficiency by guiding workers through complex assembly tasks with visual instructions superimposed on components. This innovative approach drastically reduces errors, as research indicates that 80% of production flaws stem from human mistakes, while simultaneously accelerating production timelines.

- Training and Maintenance: AR provides immersive training experiences for new employees, allowing them to practice assembly and maintenance tasks in a simulated environment. This hands-on method not only boosts retention but also equips workers to tackle real-world challenges, effectively addressing the industry's skills gap. The AR-driven In-Vehicle Onboarding System further enriches user experience by making technology approachable and easily digestible.

- Design Visualization: Designers utilize AR to visualize 3D vehicle models in real-time, facilitating immediate feedback and adjustments. This capability streamlines the design workflow, enabling rapid prototyping and minimizing material waste. For instance, the BMW Group employs AR in vehicle concept and prototype engineering to visualize changes instantly.

- Quality Control: AR enhances quality assurance by pinpointing defects or deviations from specifications during production. By enabling technicians to conduct visual inspections with digital overlays, AR substantially improves product quality and mitigates the risk of recalls.

- Remote Assistance: Technicians leverage AR for real-time guidance from experts located elsewhere, boosting problem-solving efficiency during maintenance tasks. This application not only reduces downtime but also promotes collaboration among global teams, ensuring expertise is readily accessible when required. Overall, the use of augmented reality in automobile modules can elevate sales by up to 80%, underscoring its profound impact on user engagement and operational efficiency.

Benefits of Augmented Reality in Automotive Manufacturing

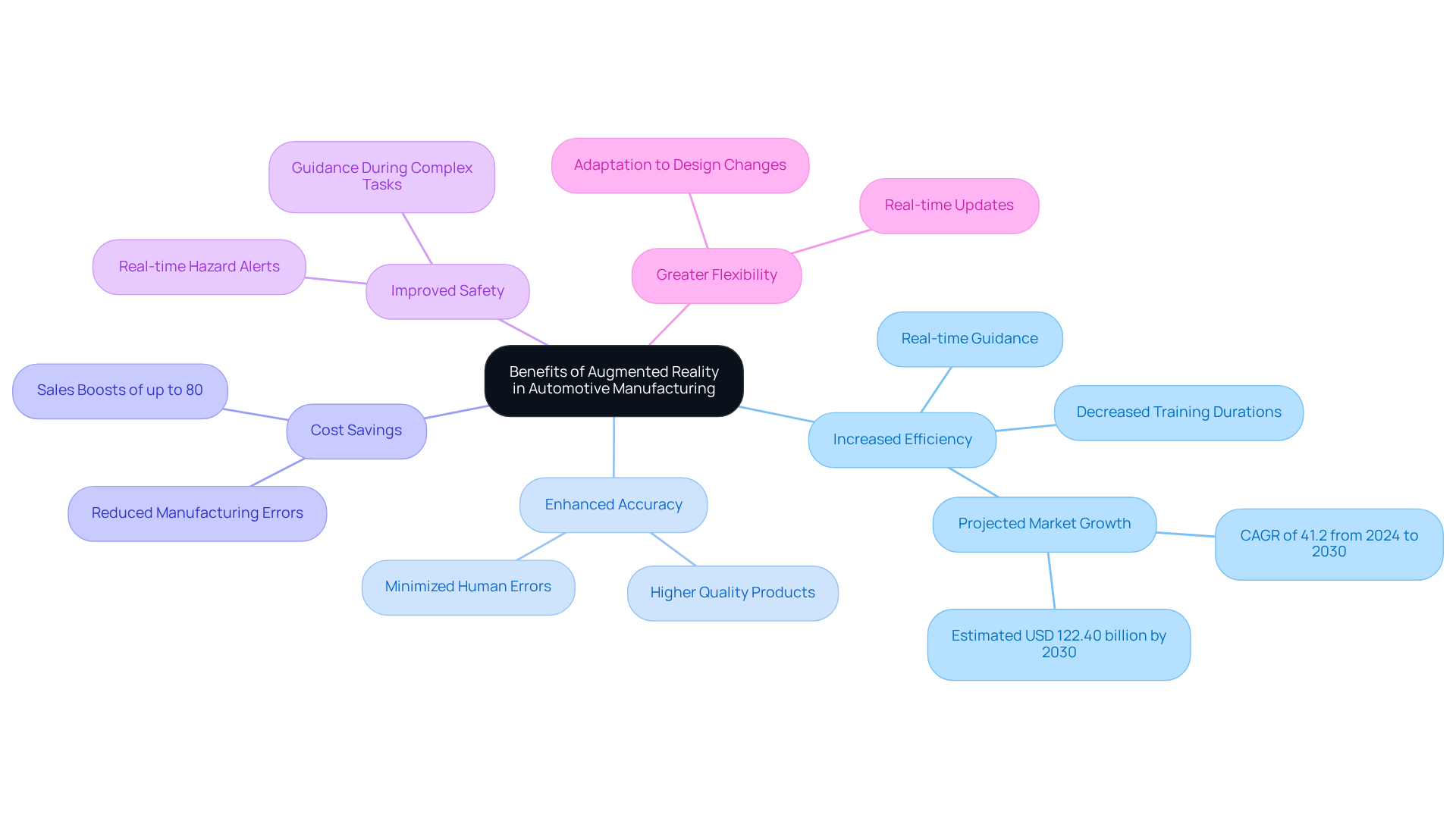

The benefits of augmented reality in automobile manufacturing are extensive and undeniable.

-

Increased Efficiency: AR enhances workflow processes by providing real-time guidance, which significantly decreases training and assembly durations. This efficiency is crucial, especially considering that the global augmented reality in automobile market is projected to grow at a compound annual growth rate of 41.2% from 2024 to 2030, reaching an estimated USD 122.40 billion by 2030.

-

Enhanced Accuracy: By overlaying digital instructions directly onto the physical environment, AR minimizes human errors, resulting in higher quality products. This accuracy is vital in a sector where precision is paramount.

-

Cost Savings: The integration of AR leads to reduced training durations and fewer manufacturing errors, translating into substantial cost savings for manufacturers. For instance, companies utilizing AR modules have reported sales boosts of up to 80%, highlighting its financial impact.

-

Improved Safety: AR enhances worker safety by providing real-time hazard alerts and guidance during complex tasks, ensuring a safer working environment.

-

Greater Flexibility: Manufacturers can swiftly adapt to design changes or production process modifications, as AR systems can be updated with new information in real-time. This agility is essential in a rapidly evolving automotive landscape, allowing for more responsive manufacturing practices.

In conclusion, embracing augmented reality in automobile not only streamlines operations but also positions manufacturers to thrive in a competitive market. The time to act is now—leverage AR to transform your manufacturing processes and drive success.

Conclusion

Augmented reality is transforming the automobile manufacturing landscape by seamlessly integrating digital information with the physical world. This technology not only enhances production processes but also improves training and boosts operational efficiency, establishing itself as an indispensable tool for modern manufacturers. With its capability to overlay visual instructions and real-time data, augmented reality simplifies complex tasks and prepares the industry for a future where precision and speed are paramount.

The evolution of augmented reality in the automotive sector is significant, tracing its origins from early heads-up displays to its current applications in:

- Assembly support

- Training

- Design visualization

- Quality control

- Remote assistance

Key benefits include:

- Increased efficiency

- Enhanced accuracy

- Significant cost savings

- Improved safety

- Greater flexibility in adapting to changes

These advantages underscore the growing importance of augmented reality in driving innovation and competitiveness within automobile manufacturing.

As the automotive industry continues to evolve, embracing augmented reality is essential. Manufacturers must invest in AR technologies to streamline their processes and enhance user engagement. By leveraging the transformative power of augmented reality, companies can position themselves at the forefront of the industry, ensuring they not only meet but exceed the demands of an ever-changing market.

Frequently Asked Questions

What is augmented reality in automobile manufacturing?

Augmented reality in automobile manufacturing is the integration of digital information with the physical environment, enhancing production activities by overlaying computer-generated images, sounds, and sensory enhancements onto real-world views.

How does augmented reality improve production activities in automobile manufacturing?

Augmented reality improves production activities by providing assembly line workers with visual instructions directly on the components they are handling, which enhances accuracy and efficiency.

What are some specific applications of augmented reality in automobile manufacturing?

Specific applications of augmented reality in automobile manufacturing include overlaying assembly instructions, facilitating quality control, and delivering instant feedback to workers.

What are the benefits of using augmented reality in automobile production?

The benefits of using augmented reality in automobile production include improved production efficiency, enhanced training and maintenance activities, and a safer and more sustainable production environment.

What is the projected growth rate for augmented reality in the automobile industry?

The incorporation of augmented reality in the automobile industry is projected to expand at a compound annual growth rate (CAGR) of 18.1% from 2021 to 2028.

Which manufacturers are currently using augmented reality in their operations?

Leading manufacturers such as Ford and Toyota are using augmented reality in their operations. Ford's Advanced Manufacturing Center focuses on AR, robotics, and 3D printing, while Toyota has partnered with Microsoft to enhance training efficiency.

Why is collaboration and investment in augmented reality technology important for the automotive industry?

Collaboration and investment in augmented reality technology are crucial for staying ahead in the competitive automotive landscape as the industry evolves and embraces innovative production methods.